Neutral Silicone Weather-resistant Sealant 6134

Product Description

Our silicone industrial sealant offers a multitude of advantages that make it a highly effective and reliable solution for a wide range of applications. With its exceptional properties, this sealant is designed to meet the rigorous demands of industrial environments.

Furthermore, our silicone industrial sealant is highly resistant to moisture, chemicals, and UV radiation. It forms a waterproof barrier that effectively prevents water or moisture infiltration, protecting sensitive equipment and materials from damage. Its resistance to chemicals and UV radiation ensures that the sealant remains intact and unaffected, even in harsh industrial environments.

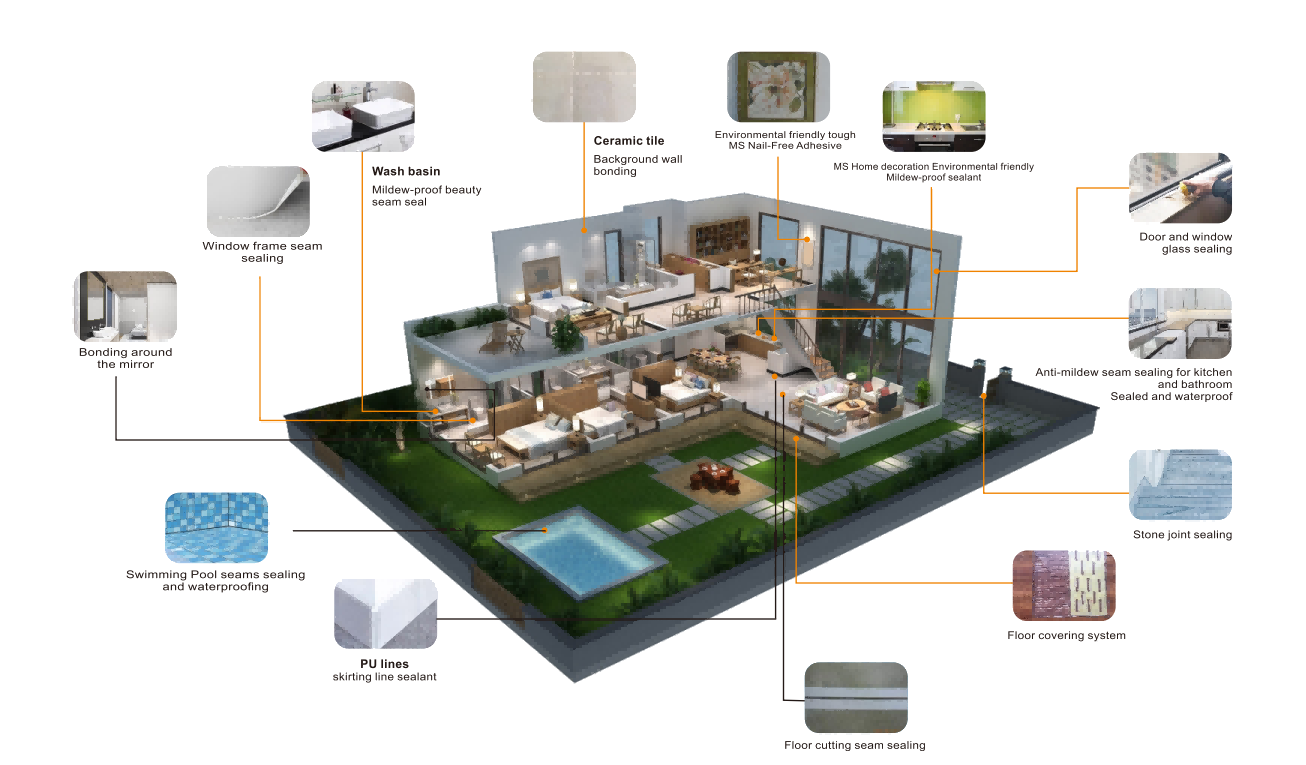

Areas of Application

Suitable for sealing of various installations of windows and doors.

Specification

Plastic tube: 240ml / 260ml / 280ml / 300ml

Sausage: 590ml

Technical Data

| Technical Data① | 6134 | |

| Items | Standard | Typical Value |

| Appearance | Black,Grey,White, homogeneous paste | / |

| Density GB/T 13477.2 | 1.50±0.10 | 1.53 |

| Extrudability(ml/min) GB/T 13477.4 | ≥150 | 300 |

| Sagging properties(mm) GB/T 13477.6 | ≤3 | 0 |

| Tack free time②(min) GBfT 13477.5 | ≤30 | 15 |

| Elastic recovery rate% GB/T 13477.17 | ≥80 | 84 |

| Volatile contents (%) GB/T 2793 | ≤8 | 3.8 |

| Shore A-hardness GBZT 531.1 | 30~45 | 40 |

| Tensile strength MPa GB/T 528 | ≥0.8 | 1.6 |

| Elongation at break % GBAT 528 | ≥300 | 350 |

| Tansile modulus ( MPa ) GB/T 13477.8 | >0.4(23°C) | 0.5 |

| Tensile properties at maintained extension GB/T 13477.10 | No failure | No failure |

| Adhesion/cohesion properties at maintained extension after water immersion GBfT 13477.11 | No failure | No failure |

| Adhesion/cohesion properties at variable temperature GB/T 13477.13 | No failure | No failure |

| Adhesion after UV irradiation JC/T485 | No failure | No failure |

①All data above were tested under standardized condition at 23±2°C, 50±5%RH.

②Value of tack free time would be affected by change of environmental temperature and humidity.

Other Details

Guangdong Pustar Adhesives & Sealants Co., Ltd. is a professional manufacturer of polyurethane sealant and adhesive in China. The company integrates scientific research, production and sales. It not only has its own R&D technology center, but also cooperates with many universities to build a research and development application system.

Guangdong Pustar Adhesives & Sealants Co., Ltd. is a professional manufacturer of polyurethane sealant and adhesive in China. The company integrates scientific research, production and sales. It not only has its own R&D technology center, but also cooperates with many universities to build a research and development application system.  The self-owned brand “PUSTAR” polyurethane sealant has been highly praised by customers for its stable and excellent quality. In the second half of 2006, in response to changes in market demand, the company expanded the production line in Qingxi, Dongguan, and the annual production scale has reached more than 10,000 tons.

The self-owned brand “PUSTAR” polyurethane sealant has been highly praised by customers for its stable and excellent quality. In the second half of 2006, in response to changes in market demand, the company expanded the production line in Qingxi, Dongguan, and the annual production scale has reached more than 10,000 tons.  For a long time, there has been an irreconcilable contradiction between technical research and industrial production of polyurethane sealing materials, which has restricted the development of the industry. Even in the world, only a few companies can achieve large-scale production, but because of their super strong Adhesive and sealing performance, its market influence is gradually expanding, and the development of polyurethane sealant and adhesives surpassing traditional silicone sealants is the general trend.

For a long time, there has been an irreconcilable contradiction between technical research and industrial production of polyurethane sealing materials, which has restricted the development of the industry. Even in the world, only a few companies can achieve large-scale production, but because of their super strong Adhesive and sealing performance, its market influence is gradually expanding, and the development of polyurethane sealant and adhesives surpassing traditional silicone sealants is the general trend.  Following this trend, Pustar Company has pioneered the “anti-experiment” manufacturing method in the long-term research and development practice, opened up a new road to large-scale production, cooperated with a professional marketing team, and has spread all over the country and exported to the United States, Russia and Canada. And Europe, the application field is popular in automobile manufacturing, construction and industry.

Following this trend, Pustar Company has pioneered the “anti-experiment” manufacturing method in the long-term research and development practice, opened up a new road to large-scale production, cooperated with a professional marketing team, and has spread all over the country and exported to the United States, Russia and Canada. And Europe, the application field is popular in automobile manufacturing, construction and industry.

Hose sealant use steps

Expansion joint sizing process steps Prepare construction tools: special glue gun ruler fine paper gloves spatula knife Clear glue utility knife brush rubber tip scissors liner Clean the sticky base surface Lay the padding material (polyethylene foam strip) to ensure that the depth of the padding is about 1 cm from the wall Pasted paper to prevent sealant contamination of non-construction parts Cut the nozzle crosswise with a knife Cut the sealant opening Into the glue nozzle and into the glue gun The sealant is uniformly and continuously extruded from the nozzle of the glue gun. The glue gun should move evenly and slowly to ensure that the adhesive base is fully in contact with the sealant and prevent bubbles or holes from moving too fast Apply clear glue to the scraper (easy to clean later) and modify the surface with the scraper before dry use Tear off the paper

Hard tube sealant use steps

Poke the sealing bottle and cut the nozzle with proper diameter Open the bottom of the sealant like a can Screw the glue nozzle into the glue gun